NNSA POLICY LETTER

Approved: 1-10-17

QUALITY MANAGEMENT SYSTEM

NATIONAL NUCLEAR SECURITY ADMINISTRATION

Office of Management and Budget

CONTROLLED DOCUMENT OFFICE OF PRIMARY INTEREST (OPI):

AVAILABLE ONLINE AT: Quality Management

https://nnsaportal.energy.gov/intranet/na-mb/na-mb-20/pages/nnsa-policy.aspx

http://nnsa.energy.gov

printed copies are uncontrolled

NAP 414.1

THIS PAGE INTENTIONALLY LEFT BLANK

1

NAP 414.1

1-10-17

QUALITY MANAGEMENT SYSTEM

1.

PURPOSE. Establish, implement, maintain, assess, and improve the Quality

Management System (QMS) for NNSA federal operations in accordance with DOE

Order (O) 414.1*, Quality Assurance and, by citation, the American version of

International Organization for Standardization (ISO) Standard Requirements Document

ISO 9001-*, Quality Management Systems – Requirements (ASQ/ANSI/ISO

9001:2015).

* Unless otherwise specified, reference is made to the current version of these

documents.

2.

CANCELLATION. NAP 26A, Quality Management System, dated 6-1-16.

3.

APPLICABILITY.

a.

Federal. This policy applies to all NNSA organizations.

b.

Contractors. This policy does not apply to contractors.

c.

Equivalency. In accordance with the responsibilities and authorities assigned by

Executive Order 12344, codified at 50 United States Code sections 2406 and

2511, and to ensure consistency through the joint Navy/DOE Naval Nuclear

Propulsion Program, the Deputy Administrator for Naval Reactors (Director) will

implement and oversee requirements and practices pertaining to this Directive for

activities under the Director's cognizance, as deemed appropriate.

4.

SUMMARY OF CHANGES.

a.

Modified contact information (refer to section 10).

b.

Changed “Office of Quality Management (OQM)” to “Quality Management.”

c.

Added Management System Description (MSD) (refer to Appendix 4).

d.

Added Acronyms (refer to Appendix 5).

e.

Added References (refer to Appendix 6).

f.

Added Document Repositories (refer to Appendix 7).

g.

Added DOE O 414.1-MSD Traceability Matrix (refer to Appendix 8).

h.

Added MSD-ISO 9001:2015 Traceability Matrix (refer to Appendix 9).

i.

Added ISO 9001:2015-ISO 9001:2008 Traceability Matrix (refer to Appendix

10).

2

NAP 414.1

1-10-17

5.

BACKGROUND. Both DOE O 414.1 and ANSI/ISO/ASQ Q9001 stipulate that quality

systems be developed. The QMS referenced in this directive pertains to an Enterprise

Management System for NNSA and is a process-based management system that controls

the quality of customer products and mission requirements. This NAP was developed

using DOE O 414.1, Quality Assurance, as a baseline and tailored to meet the mission

requirements of NNSA. The selection and use of ANSI/ISO/ASQ Q9001 to establish the

QMS is authorized by DOE O 414.1, paragraph 4.A.(2)(C):

“(c) Use appropriate national or international consensus standards in whole or

in part, consistent with regulatory requirements and Secretarial Officer

direction. When standards do not fully address these requirements, the

gaps must be addressed in the QAP.

Examples of currently acceptable standards include:

1 ASME NQA-1-2008 with the NQA-1a-2009 addenda, Quality

Assurance Requirements for Nuclear Facility Applications;

2 ANSI/ISO/ASQ Q9001-2008, Quality Management System-

Requirements; and, [sic]

3 ANSI/ASQ Z 1.13-1999, Quality Guidelines for Research.”

6.

REQUIREMENTS.

a.

The QMS is codified in the MSD (see Appendix 4) which serves as the

description of the Quality Assurance Program (QAP), stipulated in DOE O 414.1.

b.

The NNSA QMS must be in full compliance with federal requirements and

responsibilities of DOE O 414.1, and select and applicable ISO 9001 principles

for quality management systems as identified in Appendix 4.

c.

The QMS must be in compliance with the current version of the NNSA

Enterprise Strategic Vision.

d.

The MSD and associated work processes must be documented and available to all

employees.

e.

Work processes, such as process descriptions outlined in Appendix 4 and those

developed pursuant to paragraph 7.b.1, must be identified, controlled, and

measured to assure that the quality of products and services fulfills customer

requirements.

f.

Management System Assessments (MSAs) of the NNSA QMS must be performed

periodically in accordance with the ISO 9001 requirements for the conduct of

internal audits. Periodic management reviews will be conducted to assess the

status of the QMS and to address improvements to processes, products, and

services. (Appendix 2)

NAP 414.1

1

-10-17

3

g.

Subject area-specific quality systems, developed in whole or in part to comply

with DOE O 414.1, Quality Assurance, or specific technical programs or subject

areas within NNSA, will be considered subordinate to the overarching business

process focus of the QMS codified in the MSD. Quality systems must be verified

as to their function and compliance with the pertinent standards around which

they are organized.

7.

RESPONSIBILITIES.

a.

Administrator and Principal Deputy Administrator:

(1)

Establish QMS policy.

(2)

Communicate management’s commitment to the QMS.

(3)

Ensure availability of sufficient resources to support the implementation

and ongoing management of the QMS.

(4)

Conduct periodic management reviews to identify progress of the QMS

and implement any necessary changes to ensure its continuing

improvement.

b.

Deputy Administrators, Associate Administrators, and Field Office Managers:

(1)

Establish a process for implementing the NNSA QMS in their respective

offices and functions that aligns with the NNSA QMS as established in the

MSD.

(2)

Establish organizational quality objectives.

(3)

Develop, approve, and update office procedures and work processes in

accordance with the NNSA QMS requirements stated in the MSD.

(4)

Evaluate the implementation, efficiency, and effectiveness of the NNSA

QMS for their respective offices and functions, using appropriate data

analysis techniques.

(5)

Appoint a representative to serve on the NNSA Management System

Board (MSB). (See Appendix 3)

c.

NA-MB-1.2, Quality Management:

(1)

The Quality Management Director serves as the QMS Executive

Management Representative.

(2)

The Quality Management Director serves as the chair of the NNSA

Management System Board.

4

NAP 414.1

1-10-17

(3)

Ensures that the processes needed for the corporate QMS are established,

approved, implemented, and maintained.

(4)

Establishes an MSA internal audit process to ensure continuing

improvement, as required by DOE O 414.1 and the ISO 9001standard.

(5)

Defines the criteria, scope, frequency, and methodology for the MSAs.

(6)

Reports to top management on the performance of the QMS and any need

for improvement.

(7)

Ensures the promotion of awareness of customer requirements throughout

the organization.

(8)

Acts as liaison with external bodies and customers on matters relating to

the organization’s QMS.

(9)

Designates an MSA manager who:

(a)

Conducts MSAs in accordance with the ISO 9001 standard.

(b)

Verifies through the MSAs that the QMS and subordinate

organization management systems are implemented and effectively

maintained.

(c)

Schedules MSAs, taking into consideration the status and

importance of the processes and areas to be assessed as well as the

results of previous assessments.

(d)

Establishes a documented procedure that defines the

responsibilities and requirements for planning and conducting

MSAs and reporting results.

(e)

Supports the Office of the Administrator in conducting

management reviews of the QMS.

(f)

Maintains records of the MSA schedules and results.

d.

NNSA Management System Board:

(1)

Includes representatives from all Headquarters organizations and field

offices.

(2)

Shares information relating to issues or changes that have a direct impact

on management system implementation or improvement.

(3)

Ensures appropriate integration and alignment of NNSA Headquarters and

field offices with the management system policies and requirements.

NAP 414.1

1

-10-17

5

(4)

Advises Quality Management on policy matters pertaining to NNSA's

Management System.

(5)

Prepares options to present to the Management Council on management

system issues the Board cannot resolve.

8.

REFERENCES. Refer to Appendix 6.

9.

ACRONYMS. Refer to APPENDIX 5.

10.

CONTACT. Quality Management, (202) 586-1925.

BY ORDER OF THE ADMINISTRATOR:

Appendixes:

1. ISO Best Practices

2. Internal Audits

3. Management System Board (MSB) Charter

4. Management System Description (MSD)

5. Acronyms

6. References

7. Document Repositories

8. DOE O 414.1-MSD Traceability Matrix

9. · MSD-ISO 9001:2015 Traceability Matrix

10. ISO 9001:2015-ISO 9001:2008 Traceability Matrix

THIS PAGE INTENTIONALLY LEFT BLANK

Appendix 1

AP1-1

NAP 414.1

1-10-17

APPENDIX 1. ISO BEST PRACTICES

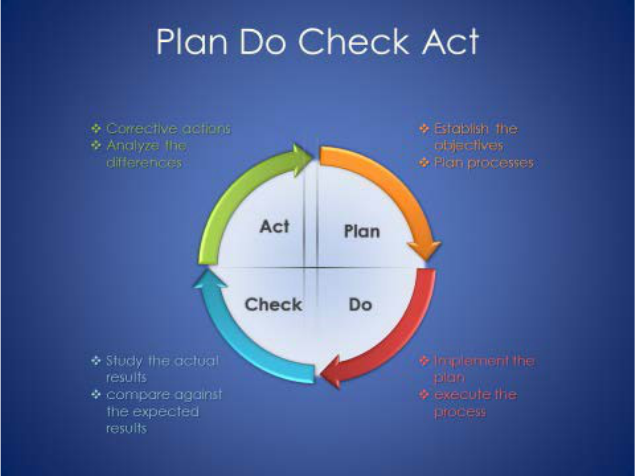

The ISO best practices can be summarized in four areas: Plan, Do, Check, Act.

Plan: Establish objectives, goals, and processes. The goal of quality management is to build a

structure that supports organizational success. Quality management requires conformance with

agency guidelines, regulations, and statutory requirements; organizational conformance with

established work processes; and responsiveness to customer needs and feedback. Quality

management creates a benchmark so that management can accurately measure the impact and

performance of its collective work processes.

Do: Formalize procedures and implement those procedures. Create and document procedures,

together with workflow training, establish a foundation upon which to build and manage

continuous improvement. Best practices also include clarity in assigned responsibilities,

effective records management, and a management system that captures organizational work

procedures in an information system readily accessible to all. Benefits of quality management

practices include the reduction of obstacles facing the workforce, documentation that facilitates a

fair distribution of workload, and the overall improvement of the work environment.

Check: Monitor and measure. Management review conducted periodically by an organization’s

managers and staff helps ensure work is aligned with mission goals and carried out according to

plan. Management review also serves to break down the stove-piped decision-making in an

organization. Audits by an independent team of reviewers are an additional way to determine if

an organization is following established processes.

Act: Pursue continuous improvement. Improvement occurs first during the development of

work processes and workflow mapping, when efficiencies are recognized and working

relationships clarified. Later, improvement stems from checks on conformance with established

work processes and customer feedback.

N

THIS PAGE INTENTIONALLY LEFT BLANK

N

Appendix 2

AP2-1

NAP 414.1

1-10-17

APPENDIX 2. INTERNAL AUDITS

MANAGEMENT SYSTEM ASSESSMENTS.

The NNSA Management System Assessment (MSA) is an activity sponsored by Quality

Management. The assessments are conducted to fulfill Quality Management’s responsibilities

and cited requirements under DOE O 414.1D, Quality Assurance, NAP 414.1, Quality

Management System, and ISO 9001:2015, Quality Management System. MSAs are conducted by

trained and certified ISO auditors and involve onsite management system reviews at the NNSA

Headquarters (HQ) facilities in Washington, DC, Germantown, MD, Albuquerque, NM, and the

field offices.

MSAs are a check, at a point in time, of an organization’s management system to verify whether

it is properly implemented, maintained, and whether mission-related processes are being

planned, documented, executed, and subjected to periodic management review. The MSA

objective is to strengthen accountability by ensuring that procedures are established and

followed. MSAs also enhance risk management, resource stewardship, and governance across

all NNSA federal organizations. These MSAs will be conducted in accordance with an

assessment plan and schedule that is developed by the NNSA Management Systems Board

(MSB). The plan will be approved by the NNSA Management Council.

MANAGEMENT SYSTEMS ASSESSMENT PROCEDURES.

Every MSA is unique and the order in which steps are performed may vary or overlap.

However, the MSA typically includes the following steps:

a.

Engagement Memo – Prior to the beginning of an MSA, appropriate organizational

points of contact are notified of the pending assessment and appraised of the MSA

objectives. Certain preliminary information may be requested at this time, such as

organization charts, internal office procedures manuals, etc.

b.

Planning – During this phase of the MSA, background information on the area to be

assessed is obtained from a number of sources in order to learn as much as possible about

the subject area or organization. Applicable policies and procedures are reviewed, as

well as pertinent statutes and regulations. The results of any prior audits of the area will

also be considered. Employees may be interviewed and MSA questionnaires may be

distributed. At length, planning culminates with an MSA scope and schedule, which is

developed in coordination with the subject organization’s staff. Every reasonable attempt

will be made by Quality Management’s assessors to minimize disruption of staff duties

and normal operations.

c.

Entrance Conference – This is a meeting between the managers of the area or

organization being assessed and MSA personnel. The scope of the MSA will be

reviewed again at this meeting and any scheduling changes or MSA-related concerns

addressed. Managers will have an opportunity to share any management system

concerns, and if there is a particular area or activity that a manager would like to have

reviewed, Quality Management will include it in the assessment plan.

Appendix 2

AP2-2

NAP 414.1

1-10-17

d.

Fieldwork – This phase may include interviewing employees, flow-charting processes,

and testing transactions. Some of the work will be performed in the area under

assessment, and some of the work will be performed in Quality Management’s office.

Appropriate managers (designated by the organization being assessed) will be kept

informed of any findings as the MSA progresses.

e.

Draft Report – Once fieldwork is completed, a draft of the MSA report will be prepared.

The report will describe organizational procedures performed, findings and observations,

as well as any recommendations or opportunities for improvement (OFIs). The draft will

be provided to the manager in charge of the area under assessment and anyone else

deemed appropriate by the manager. The subject organization will be asked to provide

written responses to Quality Management’s recommendations and will, in turn, be

included in the final report.

f.

Exit Conference – This is a meeting between management and the MSA audit personnel

to discuss the results of the assessment and go over the draft report. If management

discovers any factual errors or believes that Quality Management has misinterpreted

anything, staff should inform Quality Management during the exit conference so that

Quality Management may make corrections before the report is seen by anyone else. On

occasion, there may be items that Quality Management does not feel are appropriate to

include in the written report but should be brought to the attention of management.

Quality Management will discuss any such items during the exit conference or include a

specific issues summary in a separate management letter.

NAP 414.1

1

-10-17

Appendix 3

AP3-1

APPENDIX 3. MANAGEMENT SYSTEM BOARD (MSB) CHARTER

1.

PURPOSE.

a.

To comply with DOE O 414.1, Quality Assurance, and improve the effectiveness,

efficiency, consistency, and accountability in executing its vital roles and

responsibilities, the National Nuclear Security Administration (NNSA) is

implementing a management system in accordance with select and applicable

principles of ISO 9001, Quality Management Systems – Requirements.

b.

The Management System Board (MSB) is a successor organization to the ISO

9001 QMS Steering Committee (ISO-SC). The Steering Committee was

chartered in 2012 to lead change and provide QMS technical expertise in

developing and implementing an ISO 9001 QMS for the NNSA. As stated in its

Charter, the ISO-SC is not responsible for preparing, developing, or implementing

procedures. The Steering Committee Charter is dissolved upon the approval of

the MSB Charter.

c.

The MSB Charter establishes the NNSA MSB and defines its authorities,

applicability and scope, functions, membership, meetings, duration, and any

applicable records to be retained.

2.

APPLICABILITY AND SCOPE.

This charter applies to NNSA Headquarters’ (HQ) program offices and field offices as it

relates to management system policy implementation.

3.

AUTHORITY.

DOE O 414.1; NAP-414.1, Quality Management System; and NNSA BOP-100.1,

Senior Leadership Councils.

4.

GOVERNING COUNCIL AFFILIATION.

The MSB reports to the NNSA Management Council.

5.

FUNCTIONS.

a.

The MSB shares information relating to issues or changes that have a direct

impact on management system implementation or improvement. MSB meetings

promote the sharing of best practices as well as risk reduction or mitigation

activities concerning management systems throughout NNSA.

b.

The MSB advises Quality Management on policy matters pertaining to NNSA’s

management system.

c.

The MSB ensures appropriate integration and alignment of NNSA Headquarters

and field offices with the management system policies and requirements.

Appendix 3

AP3-2

NAP 414.1

1-10-17

d.

The MSB prepares options to present to the Management Council for

management system issues that Board members cannot resolve.

e.

MSB members act as management system liaisons for their respective offices.

6.

MEMBERSHIP.

a.

The Board is chaired by the Director, Quality Management.

b.

Each HQ program office and field office appoints a member to the MSB, as

determined appropriate by the HQ and field elements.

7.

MEETINGS.

The MSB shall meet quarterly or at the direction of the Chair.

8.

DURATION.

This charter shall continue until the Management Council cancels or amends it.

9.

ASSESSMENT.

The performance and effectiveness of the MSB shall be assessed by its members on an

annual basis and include the following considerations:

•

Meetings conducted as defined in Section 7;

•

Agendas provided in advance of the meeting;

•

Meeting notes containing action items released within three weeks of meeting

adjournment;

•

Completion of action items ensured prior to next meeting – or as agreed and

documented in meeting notes.

10.

RECORDS.

Quality Management shall maintain this charter and all other records associated with the

MSB.

11.

OFFICE OF PRIMARY INTEREST.

Quality Management.

NAP 414.1

1

-10-17

Appendix 4

AP4-1

APPENDIX 4. MANAGEMENT SYSTEM DESCRIPTION (MSD)

1.

INTRODUCTION

The National Nuclear Security Administration’s (NNSA) Management System

Description (MSD) provides a high-level description of NNSA federal business

operations. The MSD was developed in accordance with select and applicable clauses

(see Appendix 9) from the American version of the International Organization for

Standardization’s (ISO) 9001, Quality Management Systems – Requirements

(ASQ/ANSI/ISO 9001:2015). The MSD and its supporting documentation and

procedures serve the organization by providing for subordinate organizations an MSD of

NNSA’s responsibilities, the associated authorities it operates with, and its management

approaches designed to deliver the NNSA mission.

2.

PURPOSE

NNSA has engaged in multiple reform efforts to improve quality and customer

satisfaction. These reforms were designed to address shortfalls in program and support

functions management. One of the reforms included the development and completion of

an MSD.

The MSD – which satisfies the Quality Assurance Program (QAP) and Quality

Management System (QMS) requirements of Department of Energy (DOE) O 414.1,

Quality Assurance while reflecting select and applicable principles of ISO 9001 –

describes NNSA’s integrated management system, business operations, organizational

structure, and key crosscutting policies and procedures.

3.

SCOPE

The MSD describes the management, technical activities, and business practices

conducted by NNSA federal employees and contracted personnel – in NNSA HQ and

field offices – to ensure the following:

•

Implementation of the functions, responsibilities, and authorities depicted by mission

and function statements;

•

Execution of NNSA responsibilities to support customers as well as other interested

parties; and

•

Identification of the systems and mechanisms by which NNSA may ensure the quality

of products, services, and processes.

Note: Individual program or field organizations may develop and institute additional

operational guides, plans, or their own management systems that are subordinate to this

corporate MSD. Organizations with established management systems should ensure their

guides, plans, MSDs, etc., align – and are modified, as necessary – with this corporate

MSD.

Appendix 4

AP4-2

NAP 414.1

1-10-17

The following, however, have been determined to be out-of-scope:

•

Validation of Processes for Production and Service Provision

•

Identification and Traceability

•

Customer Property

•

Preservation of Product

Note: For more details, refer to paragraph 9.5.

4.

ORGANIZATION

(DOE O 414.1D Criterion 1)

4.1.

NNSA HEADQUARTERS (HQ)

NNSA manages its mission from its HQ in Washington, DC; Germantown, MD; and

Albuquerque, NM. NNSA HQ is responsible for planning, managing, and overseeing the

entire nuclear security enterprise. All program management and many functional

management responsibilities reside in HQ.

Note: For details, refer to the mission and function statements as described in an NNSA

policy.

4.2.

NNSA FIELD OFFICES

Federal field offices at each NNSA site provide tailored contract management, oversight,

and collaboration with Management and Operating (M&O) partners. In accordance with

program direction, field offices led by a field office manager (FOM) are responsible for

onsite federal oversight and administration of the M&O and other direct contracts.

4.3.

MANAGEMENT AND OPERATING (M&O) PARTNERS

Unlike government agencies outside the DOE, NNSA has a unique arrangement of being

a self-regulator. All of NNSA’s laboratories, production plants, and sites are

government-owned/contractor-operated (GOCO) and run by non-governmental

organizations under an M&O contract (or similar contract). M&O partners are tasked

with producing mission deliverables and meeting performance expectations as authorized

by NNSA officials.

Note: For more details, refer to DOE Order 226.1, Implementation of Department of

Energy Oversight Policy, and NNSA SD 226.1B, NNSA Site Governance.

4.4.

OFFICES

The offices (listed below) function synergistically to carry out the NNSA mission from

HQ (Forrestal and Germantown), the Albuquerque Complex (AC), and field office

NAP 414.1

1

-10-17

Appendix 4

AP4-3

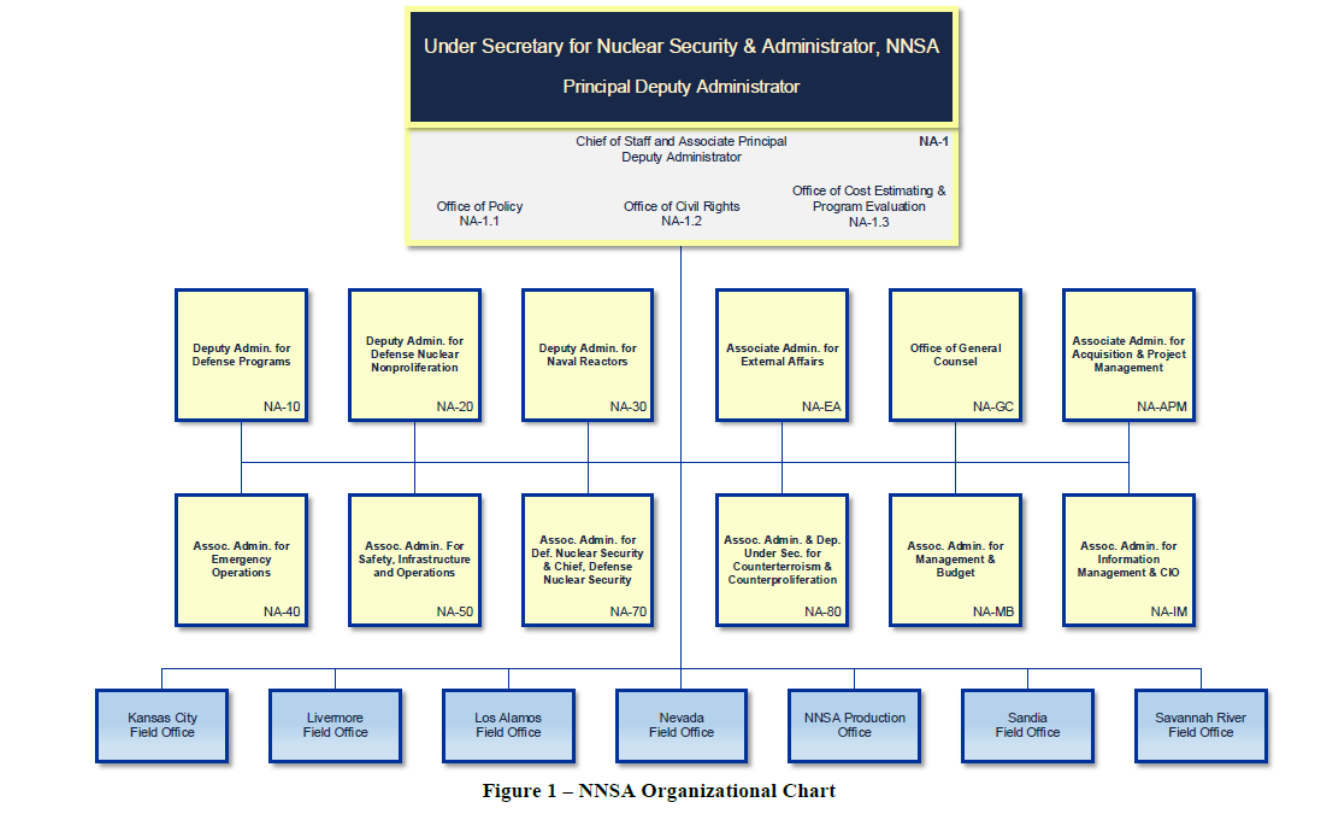

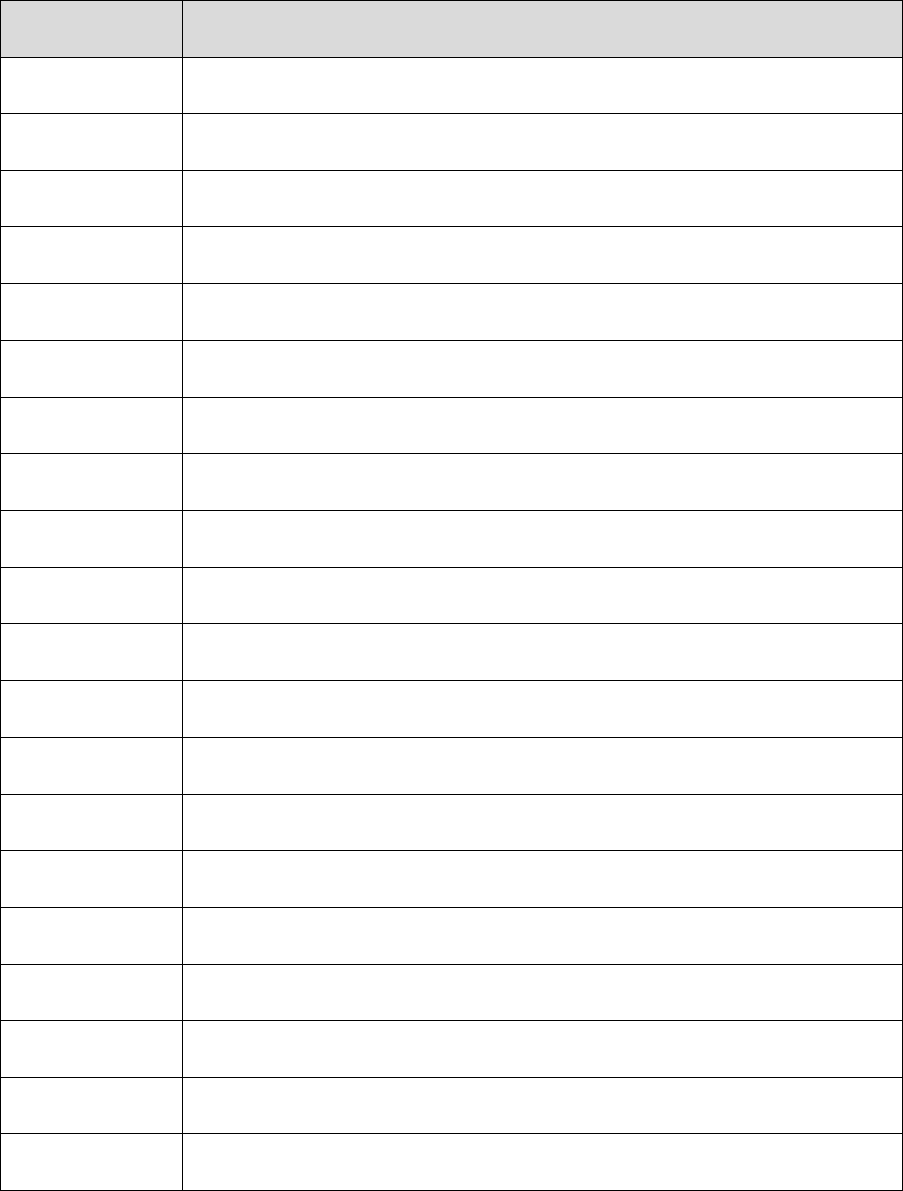

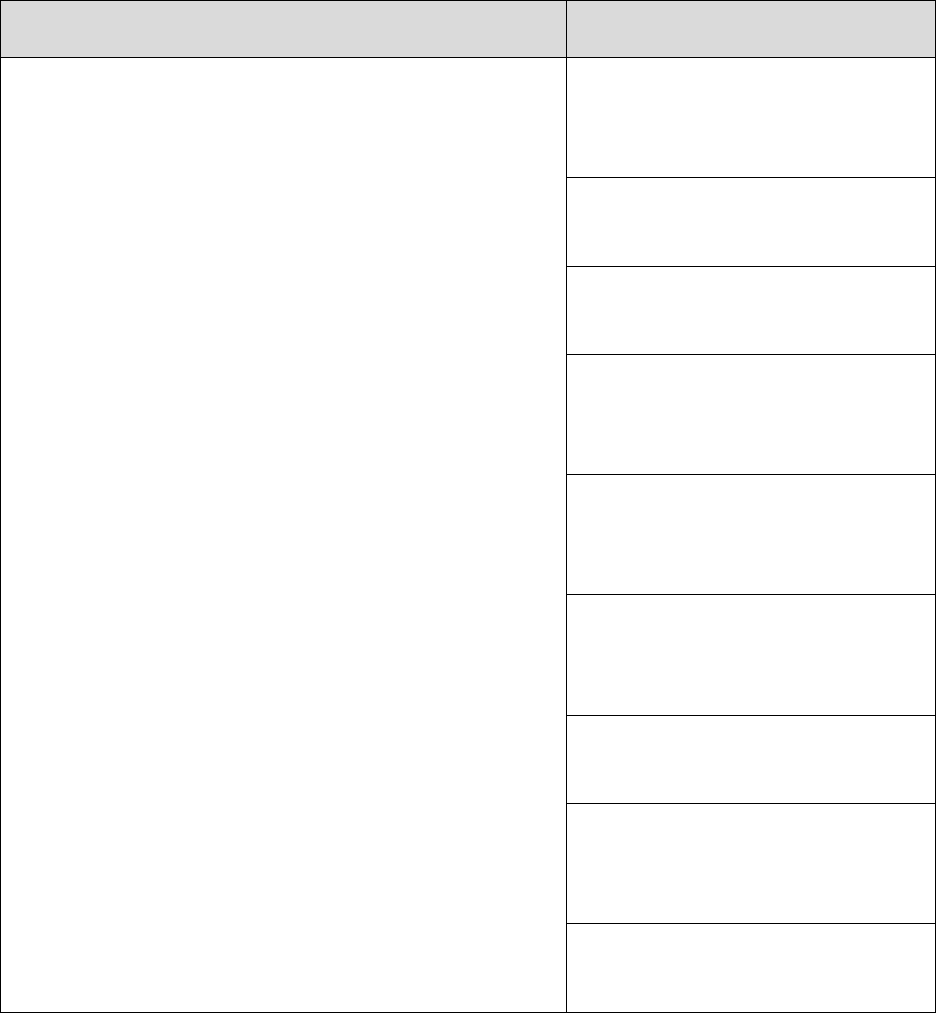

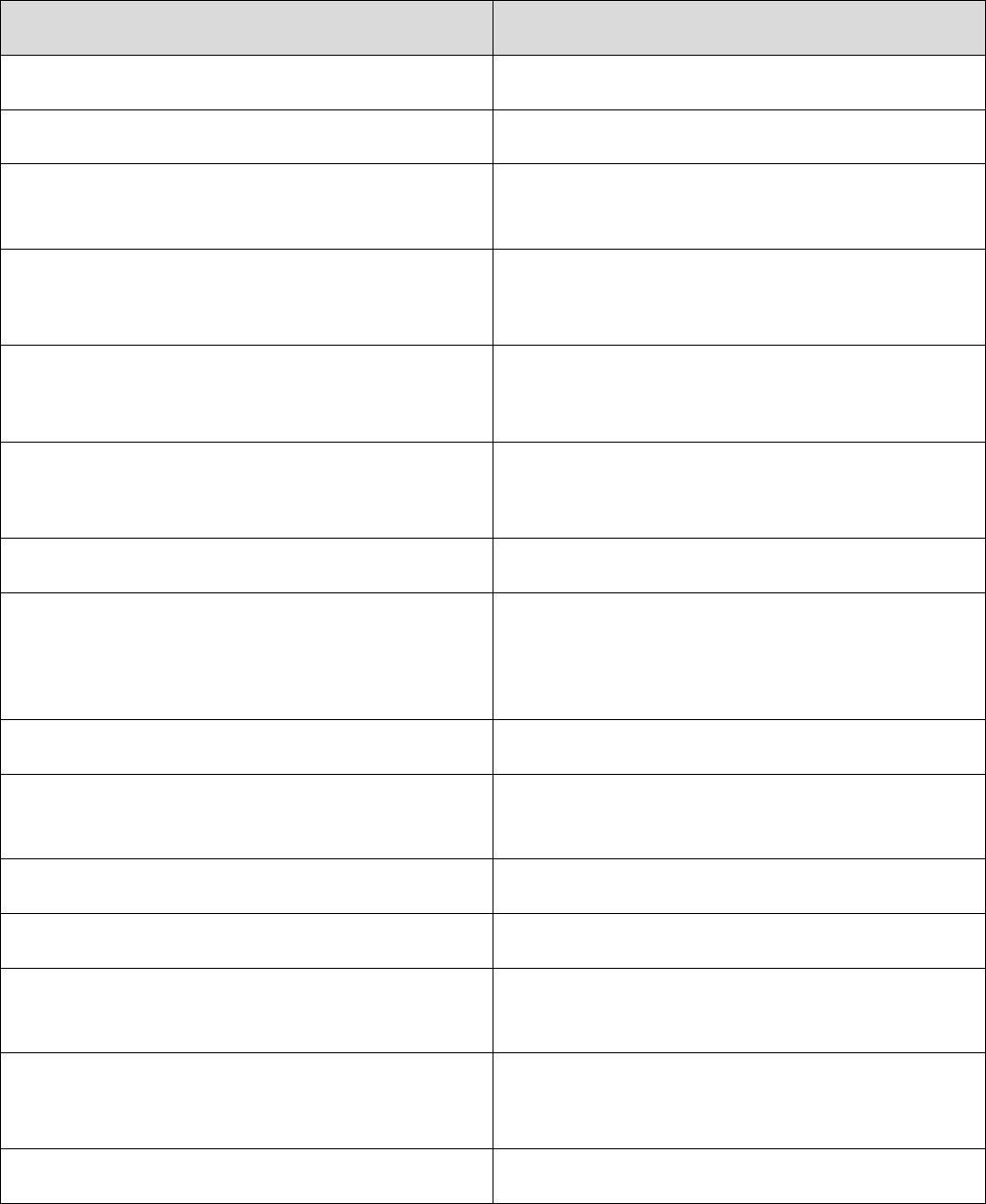

locations. The NNSA structure is illustrated in the organizational chart provided below

(Figure 1).

Note: For more details, refer to the mission and function statements as described in an

NNSA policy.

Appendix 4 NAP 414.1

AP4-4 1-10-17

Appendix 4

AP4-5

NAP 414.1

1-10-17

5.

INTEGRATED MANAGEMENT SYSTEM

(ISO 9001:2015 clause 9.3.1 and DOE O 414.1D Criterion 9)

NNSA operates as an integrated management system. The effective integration of the

individual NNSA program office, field office, and mission support management systems

allows continuous improvement, resulting in efficiency and effective achievement of

NNSA’s mission. For NNSA, policies and procedures provide a disciplined and

consistent management approach to the accomplishment of work within the requirements

established through laws, executive orders, regulations, DOE directives, and best

management practices. NNSA’s integrated management system fulfills the various

requirements of other management systems such as the:

•

Integrated Safety Management System,

•

Integrated Safeguards and Security Management System,

•

QAP, and

•

QMS.

NNSA also expects that the implementation of quality procedures such as periodic

management review and internal audits will result in continuous improvement and

enhanced risk management.

5.1.

MANAGEMENT OF NNSA

Following the decisions and guidance of the Administrator and the councils and boards,

contract managers, program managers, and functional managers work in an integrated

fashion to ensure the fulfillment of NNSA’s mission. Managers are responsible for

achieving assigned program objectives in a manner that is safe; environmentally sound;

secure; legally, ethically, and fiscally responsible; and compliant with requirements that

fall within the realm of their control. Primary responsibility rests with the lowest level

manager responsible for directing the resources needed to meet a specific requirement or

objective.

5.2.

GOVERNANCE

NNSA’s governance model is a system of strategic management, policy, and

programmatic controls exercised for the stewardship of the organization and execution of

mission. In NNSA, governance is implemented collaboratively by federal and contractor

organizations in pursuit of shared mission objectives. The NNSA governance system is

defined by documented organizational roles, responsibilities, and work processes. The

governance system is implemented through a hierarchal and disciplined structure of

councils, boards, and committees. Each group possesses distinct but interrelated

responsibility and decision making authority and has a membership that includes

appropriate representation of federal and contractor organizations. The governance

system is informed by a matrixed quality management framework designed to reduce and

eventually eliminate nonconformance to program specifications, standards, and customer

Appendix 4

AP4-6

NAP 414.1

1-10-17

expectations, yet support and preserve the degree of independence needed for the

contractor to function in a self-regulatory manner.

Note: For more details, refer to NNSA BOP-100.1.

6.

QUALITY MANAGEMENT SYSTEM (QMS)

6.1.

GENERAL REQUIREMENTS

(ISO 9001:2015 clause 4.4.1)

NNSA has developed, documented, implemented, and maintained its Quality

Management System (QMS) to ensure it aligns with select and applicable principles of

ISO 9001. With this alignment, the NNSA QMS is based upon an approach that:

•

Identifies the processes needed for the management system;

•

Determines the sequence and interaction of processes;

•

Establishes the criteria and methods required to ensure effective operation and

management of processes;

•

Ensures the availability of resources and information necessary to support processes;

and

•

Monitors, measures, and analyzes processes to achieve planned results and continual

improvement.

6.2.

DOCUMENTATION REQUIREMENTS

The level and type of documentation established for NNSA is reviewed periodically to

ensure it remains appropriate for the following:

•

Activities performed,

•

Methods used,

•

Complexity of processes and their interactions, and

•

Skills and capabilities required by personnel.

Corporate NNSA procedures are provided in one of five ways:

1.

MSD,

2.

Existing DOE directives,

3.

BOPs,

NAP 414.1 Appendix 4

1-10-17 AP4-7

4.

Procedures contained in NAPs and SDs, or

5.

Standard Operating Procedures (SOPs).

6.2.1.

NNSA POLICIES

NNSA policies are categorized as follows:

•

NAPs – establish enterprise-wide policies, requirements, and responsibilities unique

to NNSA; apply to all Federal NNSA Elements and to contractor elements when

appropriate.

•

SDs – augment policies, requirements, and responsibilities established in a DOE

directive; apply to all Federal NNSA Elements and to contractor elements when

appropriate.

•

BOPs – establish business procedures that apply to more than one Federal NNSA

Element.

•

Interim Policy Memoranda (IPMs) – establish temporary enterprise-wide policy;

apply to all Federal NNSA Elements and to contractor elements when appropriate.

•

SOPs – establish business procedures that apply to a single Federal NNSA Element.

Note: For more details, refer to NNSA SD 251.1, NNSA Policies, Supplemental

Directives, and Business Operating Procedures.

6.2.2.

QUALITY MANUAL

The MSD establishes NNSA quality management policy and serves as the quality manual

for the organization. The manual includes the scope and description of the QMS and

references documented procedures and external documents.

Note: The MSD is a controlled document subject to select and applicable principles of

ISO 9001 and DOE O 414.1.

6.2.3.

CONTROL OF DOCUMENTS

(ISO 9001:2015 clauses 7.5.3.1, 7.5.3.2, and 8.1)

Procedures are established and maintained at NNSA to control documents within the

scope of the NNSA management system. This includes the processes for preparing,

reviewing, approving, releasing, distributing, changing, revising, tracking, maintaining,

and canceling documents, quality manuals and plans, procedures, forms, and instructions.

Each NNSA organization is responsible for the establishment, maintenance, and control

of organization-unique documents to include distribution of documents of external origin.

Appendix 4 NAP 414.1

AP4-8 1-10-17

Documents are reviewed and approved for adequacy and accuracy prior to being issued

and work being performed. Approval may rely upon concurrence from technical

authorities and employee representatives performing the tasks, as appropriate. Each

organization maintains the documents, such as procedures, instructions, and forms, or

identifies the repository of the documents. Documents can be in multiple types of media.

Note: Electronic media are recommended, when available.

The documents must be controlled, using – at a minimum – the document’s title or

subject, approval date, and document number. A master list identifying the current

revision status of documents is established and readily available to preclude the use of

invalid or obsolete documents. This control must ensure:

•

Document issues and errors are readily available to essential NNSA management

system personnel and functions.

•

Invalid or obsolete documents are removed from points of issue or use, destroyed, or

otherwise ensured against unintended use.

•

Previous or obsolete versions of documents are identified as such.

Changes, revisions, and cancellations to documents will be reviewed and approved by the

same NNSA organization that performed the original review and approval, unless

designated otherwise.

Note: For details regarding the control of NNSA policies, refer to NNSA SD 251.1.

6.2.4.

CONTROL OF RECORDS

Per NNSA SD 243.1, Records Management Program, Appendix 8, Section 19, records

are defined as:

All books, papers, maps, photographs, machine-readable materials, or other

documentary materials, regardless of physical form or characteristics, made or

received by an Agency of the United States Government under Federal law or in

connection with the transaction of public business and preserved or appropriate

for preservation by that Agency or its legitimate successor as evidence of the

organization, functions, policies, decisions, procedures, operations, or other

activities of the Government or because of the informational value of the data in

them.

Records management is critical to the NNSA mission as it provides evidence (i.e.,

records) of activities, organizations, functions, policies, decisions, procedures, and

operations. The system also maintains and ensures the creation, maintenance, and proper

disposition of records. Records management best practices ensure the protection of the

legal and financial rights of the government and individuals, preserve historical legacy

information, and facilitate the effective retrieval of essential and archived information.

NAP 414.1

1

-10-17

Appendix 4

AP4-9

Note: For more details, refer to NNSA SD 243.1.

7.

LEADERSHIP AND MANAGEMENT

7.1.

LEADERSHIP AND COMMITMENT

(ISO 9001:2015 clause 5.1.1)

By issuing this document and in support of its commitment to quality and customer

satisfaction, NNSA:

•

Establishes, implements, assesses, and reports on the integrated management system

to provide accountability and improve the effectiveness of the organization.

•

Ensures compliance with applicable laws, regulations, and requirements such as the

Federal Managers’ Financial Integrity Act (FMFIA), the Office of Management and

Budget (OMB) Circular A-123, Management's Responsibility for Internal Control,

and NNSA directives.

•

Maintains a QMS that ensures that management:

o

Creates and communicates to employees NNSA’s organizational structure,

strategic objectives, and cultural environment.

o

Establishes processes for setting goals and objectives that support and align

with the organization’s mission and customer needs.

o

Implements performance measures to track achievement of goals and

objectives.

o

Provides trained and qualified personnel and supplies necessary resources.

o

Documents and implements policies, processes, and standards to identify and

manage risks.

o

Promotes continual improvement, use of processes, and practice of risk-based

thinking.

7.2.

CUSTOMER FOCUS

(ISO 9001:2015 clause 5.1.2)

NNSA’s main customers are the Secretary of Energy/DOE and Secretary of

Defense/Department of Defense (DOD). NNSA management ensures customer needs

and expectations are determined, converted into deliverable requirements, and fulfilled

with the intention of meeting or exceeding expectations.

Appendix 4

AP4-10

NAP 414.1

1-10-17

7.2.1.

QUALITY POLICY

The NNSA Quality Policy is:

To ensure NNSA products and services meet or exceed customers’ requirements and

expectations, and to achieve quality work based upon the following principles:

•

Products add value and are appropriate to the purpose of NNSA,

•

Work is conducted through an integrated and effective management system;

•

Management support for planning, organization, resources, direction, and control

is essential to quality assurance;

•

Performance and quality improvement require thorough, rigorous assessments and

effective corrective actions;

•

Personnel are responsible for achieving and maintaining quality; and

•

Risks and adverse mission impacts associated with work processes are minimized

while maximizing reliability and performance of work products.

7.2.2.

NEEDS AND EXPECTATIONS OF CUSTOMERS

The needs of NNSA customers are defined by the programmatic and regulatory

requirements for which NNSA provides advisory services, policy development and

implementation, and oversight functions. Specific needs of NNSA customers are

determined through verbal and written communications, as well as periodic visits to

relevant sites, facilities, and offices to better understand individual processes and product

or service requirements. Once requirements are identified and documented, work – at a

subordinate level – is then executed to fulfill requirements. To continually improve,

NNSA also monitors, measures, and analyzes customer satisfaction. Customer feedback,

satisfaction, needs and expectations, issues, and their impact on the NNSA management

system are reviewed periodically.

Appendix 4

AP4-11

NAP 414.1

1-10-17

7.2.3.

NEEDS AND EXPECTATIONS OF OTHER INTERESTED PARTIES

NNSA management ensures that the needs and expectations of its customers and other

interested parties are determined and incorporated, as appropriate, into planning,

processes, procedures, and product or service requirements. Needs and expectations may

impact NNSA’s ability to deliver on products and services and can often include legal

and regulatory requirements. Other interested parties may include:

•

Government organizations (e.g., White House; OMB; Members of Congress and

various congressional committees; State, Local, and Tribal Governments; foreign

governments),

•

Regulatory or oversight organizations (e.g., Defense Nuclear Facilities Safety Board

(DNFSB), Government Accountability Office (GAO), and Inspector General (IG)),

•

Non-governmental organizations (e.g., corporations, watchdog groups, unions, and

professional or industry associations), and

•

NNSA employees.

7.3.

PLANNING

7.3.1.

QUALITY OBJECTIVES

(ISO 9001:2015 clauses 6.2.1 and 6.2.2 and NAP 26A requirement 6.c.)

NNSA management establishes quality objectives at relevant functions and levels within

the organization. The objectives are derived from the NNSA Quality Policy consistent

with the NNSA Enterprise Strategic Vision. The quality objectives are documented and

reviewed by NNSA management as part of the management review process. The quality

objectives are measurable and consistent with the quality policy, and provide appropriate

focus on continual improvement and customer satisfaction.

Appendix 4

AP4-12

NAP 414.1

1-10-17

7.3.2.

PROCESSES AND PROCEDURES

(ISO 9001:2015 clauses 6.1.1 and 6.1.2 and DOE O 414.1D Criterion 1)

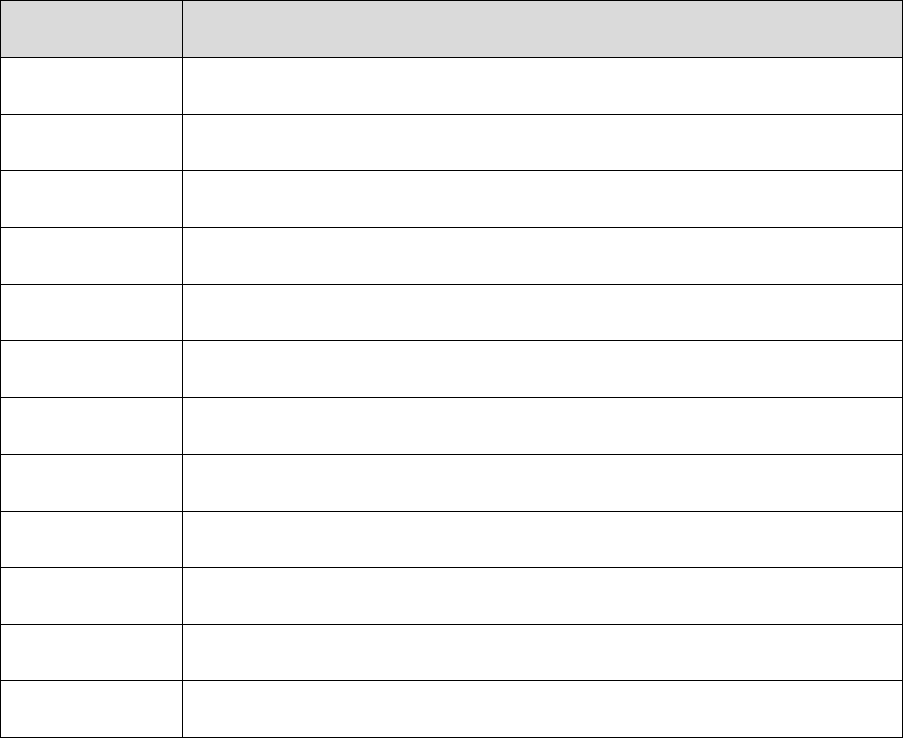

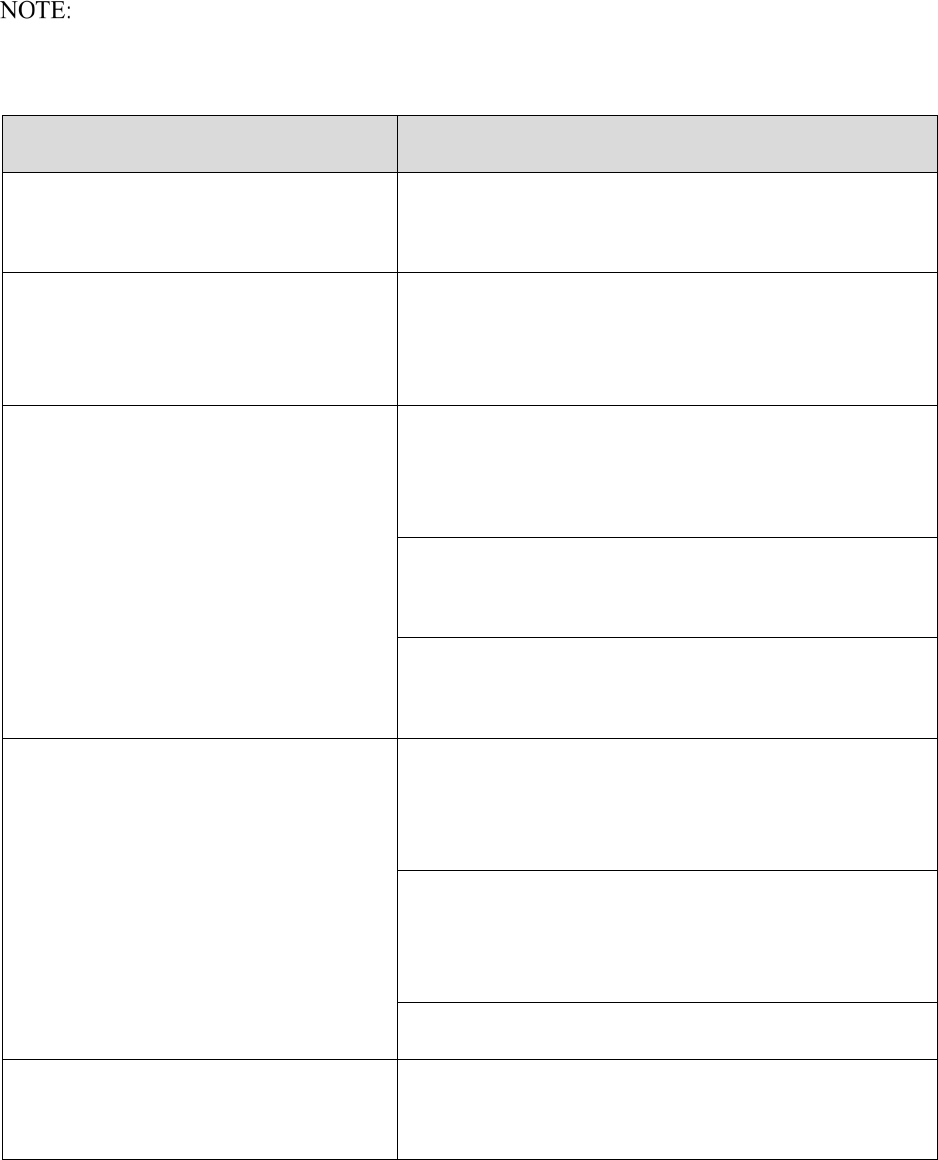

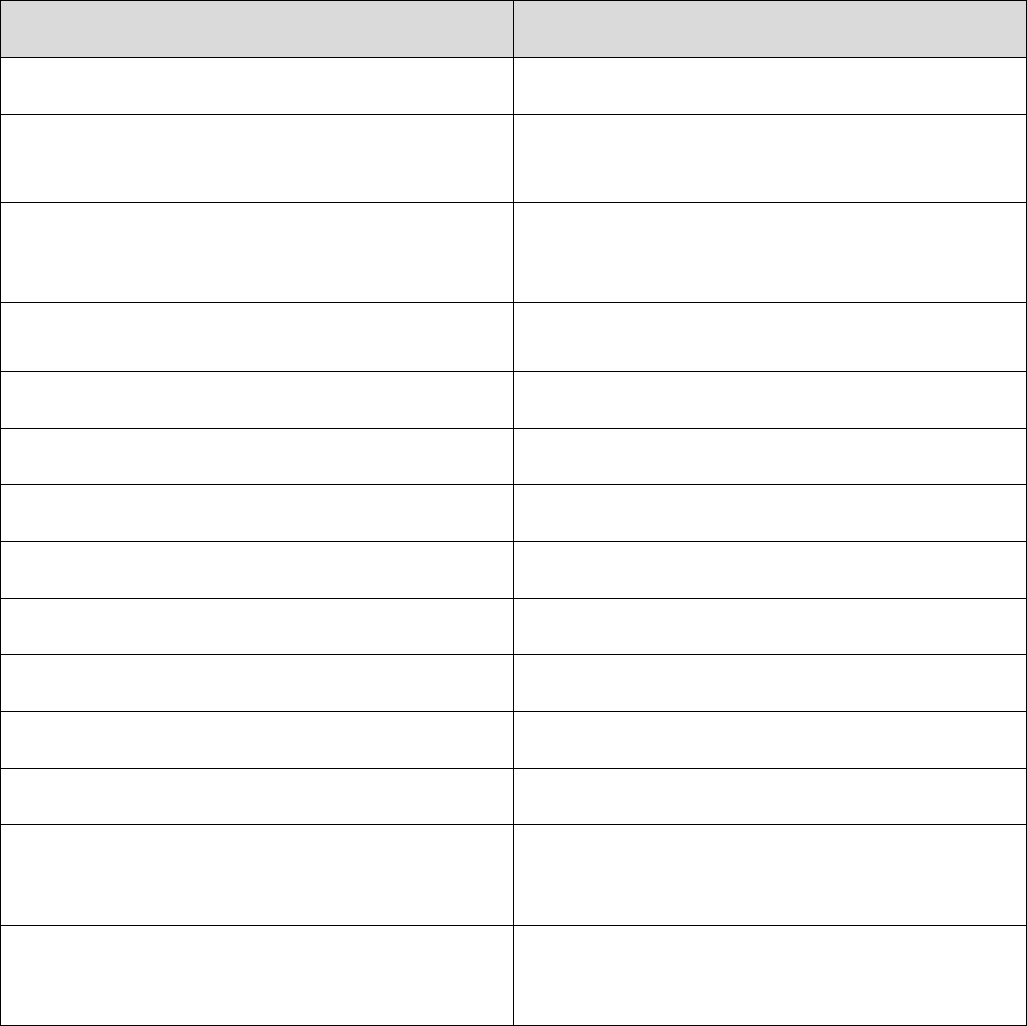

Listed below (in Table 1) are core processes and procedures used by NNSA program and

field offices to perform various functions, activities, and operations that align with NNSA

missions and goals.

Table 1 – NNSA Processes and Procedures

TITLE DESCRIPTION REFERENCE

Corporate

Performance

Evaluation

Process (CPEP)

Uniform and integrated process, which is

facilitated via a Performance Evaluation Plan

(PEP), for evaluating the performance of M&O

contractors.

NAP 540.3

Corporate

Performance

Evaluation Process

for M&O Contractors

Independent

Cost Estimate

(ICE)

Requires Independent Cost Estimates (ICEs) for

projects and programs exceeding predetermined

expected cost thresholds with participation from

organizations external to the program office and –

when appropriate – an Independent Cost Review

(ICR) by the Office of Cost Estimating and

Program Evaluation (CEPE).

NAP-28,

Responsibilities for

Independent Cost

Estimates

Planning,

Programming,

Budgeting, and

Evaluation

(PPBE)

The NNSA PPBE process – similar to PPBE

processes used by other federal government

agencies – is a continuous cycle that consists of

four major activities:

•

Planning,

•

Programming,

•

Budgeting, and

•

Evaluation.

NAP 130.1,

Planning,

Programming,

Budgeting, and

Evaluation (PPBE)

Process

Program and

Project

Management

NNSA has established program and project

management oversight processes to ensure the

experience, diverse perspectives, and thoughtful

programmatic and technical judgment at all levels

are accessible, available, and applied to program

and project activities.

BOP 413.7, Project

Management for the

Acquisition of Capital

Assets

NAP 414.1

1

-10-17

Appendix 4

AP4-13

TITLE DESCRIPTION REFERENCE

Risk

Management

Encourages continuous improvement in agency

decision-making, operations, and performance

by providing:

•

Increased likelihood of successfully

delivering on goals and objectives,

•

Decreased unanticipated outcomes,

•

Improved ability to assess risks associated

with changes,

•

Enhanced ability to communicate to

customers and others regarding NNSA’s

risk management activities, and

•

Improved risk mitigation, particularly

regarding impact of realized negative

events.

DOE G 413.3-7, Risk

Management Guide

7.4.

RESPONSIBILITY, AUTHORITY, AND COMMUNICATION

7.4.1.

RESPONSIBILITY AND AUTHORITY

(ISO 9001:2015 clause 5.3)

The basis for NNSA responsibilities and authorities is provided in the mission and

function statements maintained by the Office of the Associate Administrator for

Management and Budget (NA-MB). Functions, responsibilities, and authorities are

flowed down for implementation through the NNSA management system and various

NNSA NAPs, SDs, BOPs, or SOPs.

Note: For more details, refer to the mission and function statements as described in an

NNSA policy.

Appendix 4

AP4-14

NAP 414.1

1-10-17

7.4.2.

COMMUNICATION

(ISO 9001:2015 clauses 5.2.2 and 7.4)

NNSA management ensures that communication is maintained throughout the

organization regarding the processes of the NNSA management system and their

effectiveness. NNSA has established the following in regards to its communication

practices:

•

What to communicate, including:

o

Progress regarding activities and products;

o

Audit/assessment results;

o

Organizational updates; and

o

Missions and initiatives (e.g., NNSA Strategic Vision, memorandums, etc.).

•

When to communicate, including:

o

Daily,

o

Bi-Weekly,

o

Monthly,

o

Quarterly, and

o

Yearly.

•

Who communicates and with whom to communicate, including:

o

Administrators,

o

Managers,

o

Chief Operating Officers, and

o

Directors.

•

How to communicate, including:

o

Reports (e.g., status reports, audit reports, meeting minutes, etc.);

o

Meetings (e.g., Management Council, NNSA Council, Operations Board.,

town hall, all hands, various working groups and committees, etc.); and

NAP 414.1

1-10-17

Appendix 4

AP4-15

o

Electronic distribution/media (e.g., NNSACASTs, PowerPedia, NNSA

Connects, OneHR, Enterprise Portal (SharePoint) online communication and

collaboration sites, newsletters, procedures, and training).

8.

RESOURCES

8.1.

PROVISIONING OF RESOURCES

(ISO 9001:2015 clause 7.1.1 and DOE O 414.1D Criteria 1 and 7)

NNSA is responsible for providing sufficient resources, including trained and qualified

personnel for performing management work and for verification activities. More

specifically, resources are provided to implement, maintain, and improve the effective

operations of NNSA management system processes, and to enhance customer satisfaction

by meeting or exceeding requirements. Resources are assessed and reviewed on a

periodic basis consistent with a management review process and management’s strategic

planning activities.

8.2.

HUMAN RESOURCES

8.2.1.

ASSIGNMENT OF PERSONNEL

(ISO 9001:2015 clause 7.1.2)

The following criteria are reviewed to determine if personnel are qualified and competent

resources:

•

Education,

•

Training,

•

Observed skills, and

•

Experience.

Assignees to NNSA are expected to provide and support services based on the alignment

of their:

•

Knowledge,

•

Skills,

•

Ability to meet the needs and requirements of the task,

•

Experience with the customer,

•

Current workload, and

Appendix 4

AP4-16

NAP 414.1

1-10-17

•

Availability.

8.2.2.

COMPETENCE, AWARENESS, AND LEARNING

(ISO 9001:2015 clause 7.1.2, 7.2, and 7.3 and DOE O 414.1D Criterion 2)

NNSA management provides for the training of personnel performing activities affecting

quality of services. Training is provided either on- or off-the-job, internally, or

externally, as appropriate.

NNSA offers a wide array of sponsored programs, products, and services to its federal

workforce. The expanse of learning activities underscores NNSA’s commitment to being

a learning organization: actively promoting learning opportunities to enable performance

of NNSA’s dynamic missions. NNSA’s learning program is fully funded to ensure that

organizations can leverage resources and that centrally funded programs and courses are

available to the workforce.

Note: For more details, visit the OneLeadership “NNSA Sponsored Learning

Activities” webpage.

A dynamic website and continuous communications promote awareness of upcoming and

long-range opportunities so that employees and supervisors can consider, plan, and attend

events to increase current job competence and long-range professional development.

Note: For more details, visit the OneLearning Initiative (OLI) website or OneHR &

OneLearning message repository.

Personnel are required to complete an Individual Development Plan (IDP), which is

updated periodically and approved by their supervisor. The IDP is used to identify and

plan for training and developmental activities that reflect career goals and performance

plans of the employee. IDP approval rates are sent semi-monthly to organizational

leaders to promote the importance of employee development. IDPs are aggregated to

form the basis for an Annual Training Assessment (ATA), which tracks NNSA-wide

learning and development needs for employees, groups, and organizations. By

integrating it with IDPs, the ATA forms the basis for fiscal year (FY) allocations. NNSA

also tracks training-related cancellations and denials to discern reasons for training not

supported or attended.

NNSA emphasizes competencies as a means for talent development. For example, a

foundational competency model applicable to the entire NNSA federal workforce will be

deployed during FY2017. Functionally oriented technical competency models and

attendant career paths are being developed, with initial implementation planned for

FY2017.

Note: For details, refer to NNSA SD 360.1, Federal Employee Training.

NAP 414.1

1

-10-17

Appendix 4

AP4-17

For select technical personnel, qualification processes are conducted in accordance with

DOE O 426.1 (Change 1), Federal Technical Capability. Each person assigned to an

NNSA technical position identified by the Federal Technical Capability Program must

meet at least one appropriate qualification. Staff personnel are expected to qualify within

the prescribed qualification period. NNSA technical personnel are responsible for

ensuring their technical qualifications remain current, including arranging for and

meeting requalification requirements. Where a formal requalification requirement does

not exist, maintenance of qualification is accomplished through successful participation

in continuing education as assigned by supervisors and certified by a Qualifying Official,

and verified by the NNSA Federal Technical Capability (FTC) Panel Agent.

Documented procedures are maintained to identify training requirements and ensure

appropriate training of personnel performing NNSA work. Training and qualification

records are created and maintained by the DOE’s National Training Center using the

e-TQP electronic records system.

9.

OPERATIONS

(DOE O 414.1D Criteria 5 and 6)

9.1.

PLANNING OF PRODUCT AND SERVICE REALIZATION

(ISO 9001:2015 clause 8.1 and DOE O 414.1D Criteria 5 and 6)

Planning is required before new services, products, or processes are implemented.

During the planning phase, management or assigned personnel identify requirements for

the following:

•

Product or services;

•

Affected processes, procedures, and resources;

•

Monitoring, measurement, or review requirements;

•

Product or service expectations or acceptance criteria;

•

Deliverable requirements; and

•

Schedule, as applicable.

Appendix 4

AP4-18

NAP 414.1

1-10-17

9.2.

DETERMINATION OF REQUIREMENTS RELATED TO PRODUCTS AND

SERVICES

(ISO 9001:2015 clause 8.2.2 and DOE O 414.1D Criteria 5 and 6)

The product of NNSA is safe and secure execution of its mission objectives. The

requirements of NNSA products and services are defined by the programmatic and

regulatory requirements for which NNSA provides advisory services, policy development

and implementation, and oversight functions. Requirements are incorporated into DOE

and NNSA directives and customer-specific processes and procedures, which NNSA

follows, as necessary, for the creation and delivery of products and services. Other

requirements not detailed in directives, or unique to a given product/service or customer,

are ascertained through communication with the customer and research or knowledge of

industry standards or other relevant resources.

9.3.

REVIEW OF REQUIREMENTS RELATED TO PRODUCTS AND SERVICES

(ISO 9001:2015 clause 8.2.3 and DOE O 414.1D Criteria 5 and 6)

Relevant requirements are identified and discussed with customers, as appropriate. Work

is performed when NNSA and the customer organization have reached agreement in

principle.

9.4.

CUSTOMER COMMUNICATION

(ISO 9001:2015 clause 8.2.1 and DOE O 414.1D Criteria 5 and 6)

NNSA appoints various staff members to serve as leads or points of contact (POCs) for

functional areas or NNSA customer organizations. POCs are responsible for interfacing

with key POCs from customer organizations to establish and maintain awareness of needs

and opportunities for providing assistance or improving support. The NNSA leads and

POCs serve as the primary focal point for communication between NNSA and the

customer’s staff. NNSA staff providing support to a customer interface with the

customer regarding an assigned task or project to ensure customer needs, requirements,

and expectations are met.

9.5.

CONTROL OF PRODUCTION AND SERVICE PROVISIONING

(ISO 9001:2015 clause 8.5.1 and DOE O 414.1D Criteria 5 and 6)

NNSA develops and implements SOPs for use in the creation and delivery of products

and services. SOPs are the responsibility of individual NNSA offices and are controlled

and maintained using best practices consistent with those processes stated in Section

6.2.3. The need for SOPs increases with regulatory requirements driving the product or

service – or the associated level of prescription. Therefore, SOPs are associated with

processes and products or services under NNSA policy development and implementation

or oversight roles.

NAP 414.1

1

-10-17

Appendix 4

AP4-19

The following do not apply to the control of NNSA production and service provisioning:

•

Validation of Processes for Production and Service Provision – NNSA

products/services can be verified, monitored, and measured subsequent to realization.

•

Identification and Traceability – NNSA products or services are discrete, unique

products, and it would not be appropriate nor add value by applying identification and

traceability. Process controls are in place to ensure products remain discrete and

unique.

•

Customer Property – No customer property is maintained by NNSA in the course of

its business operations.

•

Preservation of Product – NNSA products and services are not subject to

deterioration or loss of conformity.

•

Control of Monitoring and Measuring Equipment – No monitoring or measuring

devices are used in product and service realization.

10.

MONITORING, MEASUREMENT, ANALYSIS, AND EVALUATION

(ISO 9001:2015 clause 9.1.1 and DOE O 414.1D Criteria 8 and 10)

NNSA defines, plans, and implements appropriate methods to monitor, measure, analyze,

and improve its processes to ensure product or service conformance and to continually

improve the overall effectiveness of the NNSA management system.

10.1.

MONITORING AND MEASUREMENT

(DOE O 414.1D Criteria 3, 8, and 10)

10.1.1.

CUSTOMER SATISFACTION

(ISO 9001:2015 clause 9.1.2)

Specific needs of NNSA customers are determined through verbal and written

communications, as well as periodic visits to relevant sites, facilities, and offices to better

understand individual processes, thus ensuring the accuracy and quality of products and

services and overall satisfaction of the customer. NNSA monitors, measures, and

analyzes customer satisfaction through various means.

Appendix 4

AP4-20

NAP 414.1

1-10-17

10.1.2.

INTERNAL AUDIT

(ISO 9001:2015 clauses 9.2.1 and 9.2.2 and DOE O 414.1D Criteria 3, 8, and 10)

NNSA conducts periodic internal audits or schedules equivalent audits by other NNSA

offices or external contractors. The purpose of the internal audit is to determine whether

the NNSA management system is being effectively implemented and maintained.

Internal audits are planned and scheduled based on the status and importance of the

activity to be audited. Audits are performed by trained personnel who are independent of

the activity being audited. Because NNSA auditor resources may not always be

available, the internal audit function may be performed by other qualified parties to

assure independence.

The results of the internal audits are documented in a report, which is provided to

management for action. Management personnel responsible for the audited activity are

responsible for defining and implementing corrective action.

Follow-up activities verify and record the implementation of the corrective action, report

the verification results, and close out the audit. Subsequent audits verify the

effectiveness of the corrective actions taken. Results of internal audits and the corrective

action are submitted for management review. NNSA implements its internal audit

program in accordance with Quality Management’s (NA-MB-1.2) Management System

Assessment Guide.

10.1.3.

MONITORING AND MEASUREMENT PROCESSES

(ISO 9001:2015 clause 8.5.1 and DOE O 414.1D Criteria 3, 8, and 10)

NNSA applies methods for monitoring and, whenever applicable, measurement of

management system processes (see Appendix 2). Methods demonstrate the ability of the

processes to achieve planned results. When planned results are not achieved, corrective

action is taken to ensure conformity of the product or service.

10.1.4.

MONITORING AND MEASUREMENT OF PRODUCTS/SERVICES

(ISO 9001:2015 clause 8.5.1 and DOE O 414.1D Criteria 3, 8, and 10)

The primary deliverables for NNSA are documents (e.g., technical evaluations, reports,

memoranda, etc.). At HQ and AC, personnel work with internal and external customers

to understand the requirements for each deliverable and task to satisfy needs.

Deliverables undergo an iterative concurrence process that typically includes subject

matter experts (SMEs), supervisors, customers, or other affected parties, as appropriate,

to ensure requirements are met. Comments are resolved and incorporated into

deliverables, which are finalized and issued.

Appendix 4

AP4-21

NAP 414.1

1-10-17

10.2.

CONTROL OF NON-CONFORMING PRODUCTS/SERVICES

(ISO 9001:2015 clauses 10.2.1 and 10.2.2 and DOE O 414.1D Criteria 3, 8, and 10)

NNSA minimizes the potential for nonconforming products by interfacing with

customers to determine and understand requirements, needs, and expectations prior to

work initiation. NNSA ensures products and services that do not meet requirements are

identified, controlled whenever possible to prevent unintended use or delivery to the

customer, and corrected.

10.3.

DATA ANALYSIS

(DOE O 414.1D Criteria 3, 8, and 10)

NNSA collects and analyzes appropriate data to determine the suitability and

effectiveness of the NNSA management system and to identify improvements. Data is

derived from multiple sources including process metrics, internal audits, external audits,

customer surveys, employee feedback, etc. Data are periodically analyzed during NNSA

management staff meetings or management review meetings to provide information on

customer satisfaction, conformance to requirements, performance of processes, quality of

products and services, and trends, and to derive and implement corrective action.

10.4.

EVALUATION AND CONTINUAL IMPROVEMENT

(ISO 9001:2015 clause 10.3 and DOE O 414.1D Criteria 3, 8, and 10)

NNSA management conducts evaluations and facilitates continual improvement, which is

achieved through the use and execution of the quality policy, objectives, audit results,

analysis of data, corrective and preventive action, and management reviews.

10.5.

CORRECTIVE ACTION

(ISO 9001:2015 clauses 10.2.1 and 10.2.2 and DOE O 414.1D Criteria 3, 8, and 10)

The need for corrective action can be identified via the following:

•

Internal or external audit;

•

Customer or employee identification of unacceptable products, services,

procedures, or process results; or

•

Receipt or acceptance inspection of vendor-provided products or services against

procurement specifications.

Appendix 4

AP4-22

NAP 414.1

1-10-17

NNSA management takes action to correct or mitigate an identified issue and restore a

product, service, procedure, or process to an acceptable level of compliance. Corrective

actions are commensurate with the magnitude of the issue. Corrective action includes:

•

Review of issues (including customer complaints);

•

Identification of root cause;

•

Evaluation of the need for corrective action;

•

Determination and implementation of corrective action, if required;

•

Tracking, verifying, and closeout of corrective action taken; and

•

Follow-up effectiveness reviews.

Note: For more details, refer to DOE O 226.1 and DOE O 232.2, Occurrence

Reporting and Processing of Operations Information.

NAP 414.1

1

-10-17

Appendix 5

AP5-1

APPENDIX 5. ACRONYMS

ACRONYM DEFINITION

AC Albuquerque Complex

BOP Business Operating Procedure

CEPE Cost Estimating and Program Evaluation

DNFSB Defense Nuclear Facilities Security Board

DOD Department of Defense

DOE Department of Energy

FOM Field Office Manager

FRA Functions, Responsibilities, and Authorities

GAO Government Accountability Office

GOCO Government-Owned/Contractor-Operated

HQ Headquarters

ICE Independent Cost Estimate

ICR Independent Cost Review

IDP Individual Development Plan

IG Inspector General

IPM Interim Policy Memoranda

ISO International Organization of Standardization

ISO-SC ISO 9001 Quality Management System Steering Committee

M&O Management and Operating

MSB Management System Board

Appendix 5

AP5-2

NAP 414.1

1-10-17

ACRONYM DEFINITION

MSD Management System Description

NA-MB Office of the Associate Administrator for Management and Budget

NAP NNSA Policy

NNSA National Nuclear Security Administration

OFI Opportunity for Improvement

OMB Office of Management and Budget

PEP Performance Evaluation Plan

POC Point of Contact

PPBE Planning, Programming, Budgeting, and Evaluation

SD Supplemental Directive

SME Subject Matter Expert

SOP Standard Operating Procedure

NAP 414.1

1

-10-17

Appendix 6

AP6-1

APPENDIX 6. REFERENCES

ID TITLE

ASME NQA-1-

2008 (with the

NQA-1a-2009

addenda)

Quality Assurance Requirements for Nuclear Facility Applications

ANSI/ASQ Z1.13-

1999

Quality Guidelines for Research

BOP 100.1 Senior Leadership Councils

BOP 413.7 Project Management for the Acquisition of Capital Assets

DOE G 413.3-7A Risk Management Guide

DOE O 226.1A Implementation of Department of Energy Oversight Policy

DOE O 226.1B Implementation of Department of Energy Oversight Policy

DOE O 232.2

(Admin Change 1)

Occurrence Reporting and Processing of Operations Information

DOE O 414.1D Quality Assurance

DOE O 426.1

(Change 1)

Federal Technical Capability

ISO

31000:2009(en)

Risk Management — Principles and Guidelines

ISO 9001:2008 Quality Management Systems – Requirements

ISO 9001:2015 Quality Management Systems – Requirements

N/A NNSA Office of Quality Management, Management System

Assessment Guide

N/A U.S. Department of Energy National Nuclear Security

Administration Enterprise Strategic Vision, August 2015

Appendix 6

AP6-2

NAP 414.1

1-10-17

ID TITLE

NAP-28 Responsibilities for Independent Cost Estimates

NAP 540.3 Corporate Performance Evaluation Process for M&O Contractors

NNSA SD 226.1B NNSA Site Governance

NNSA SD 243.1 Records Management Program

NNSA SD 251.1

(Admin Change 1)

Policy Letters: NNSA Policies, Supplemental Directives, and

Business Operating Procedures

NNSA SD 360.1 Federal Employee Training

NNSA SD 450.2 Functions, Responsibilities, and Authorities (FRA) Document for

Safety Management

NAP 414.1

1

-10-17

Appendix 7

AP7-1

APPENDIX 7. DOCUMENT REPOSITORIES

TYPE REPOSITORY

BOP https://nnsaportal.energy.gov/intranet/NA-

MB/Active%20Policies/Forms/Active%20by%20Type.aspx

DOE

Guide/

Order

https://www.directives.doe.gov/

Note: After accessing the site above, click “Directives.”

NAP http://www.nnsa.energy.gov/aboutus/ouroperations/managementandbudget/polic

ysystem/nnsapolicies

SD http://www.nnsa.energy.gov/aboutus/ouroperations/managementandbudget/suppl

ementaldirectives

THIS PAGE INTENTIONALLY LEFT BLANK

NAP 414.1

1

-10-17

Appendix 8

AP8-1

APPENDIX 8. DOE O 414.1-MSD TRACEABILITY MATRIX

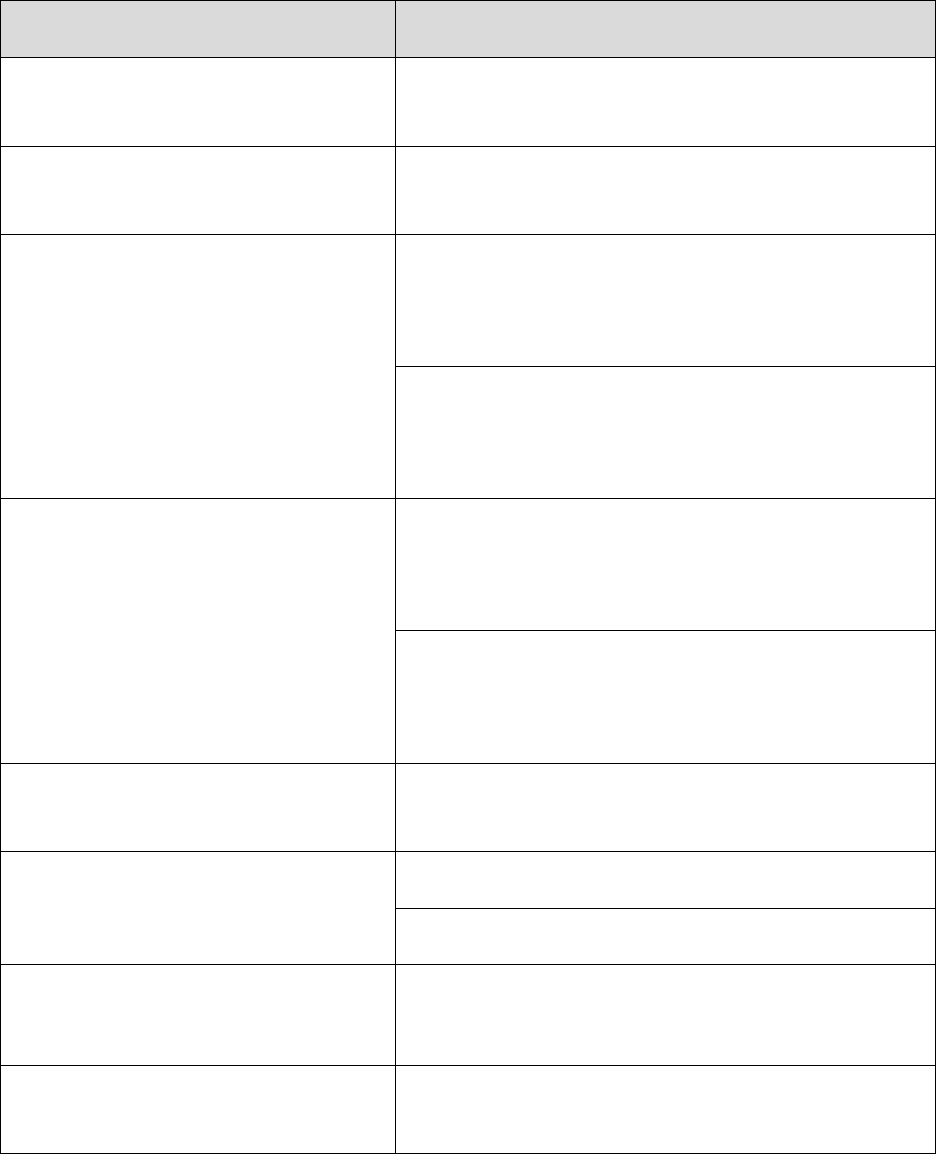

The applicable requirements from DOE O 414.1 are identified in this appendix to

demonstrate a crosswalk between DOE O 414.1 and the MSD. It contains no additional

requirements.

DOE O 414.1 (ATTACHMENT 2) MSD

Criterion 1 — Management/Program.

a.

Establish an organizational structure, functional

responsibilities, levels of authority, and interfaces for

those managing, performing, and assessing the work.

b.

Establish management processes, including planning,

scheduling, and providing resources for the work.

Appendix 4, paragraph 4,

Organization

Appendix 4, paragraph 7.3.2,

Processes and Procedures

Appendix 4, paragraph 8.1,

Provisioning of Resources

Criterion 2 — Management/Personnel Training and

Qualification.

a.

Train and qualify personnel to be capable of

performing their assigned work.

b.

Provide continuing training to personnel to maintain

their job proficiency.

Appendix 4, paragraph 8.2.2,

Competence, Awareness, and

Learning

Appendix 8

AP1-8-2

NAP 414.1

1-10-17

DOE O 414.1 (ATTACHMENT 2) MSD

Criterion 3 — Management/Quality Improvement.

a.

Establish and implement processes to detect and

prevent quality problems.

b.

Identify, control, and correct items, services, and

processes that do not meet established requirements.

c.

Identify the causes of problems, and include

prevention of recurrence as a part of corrective action

planning.

d.

Review item characteristics, process implementation,

and other quality related information to identify items,

services, and processes needing improvement.

Appendix 4, paragraph 10.1,

Monitoring and Measurement

Appendix 4, paragraph 10.1.2,

Internal Audit

Appendix 4, paragraph 10.1.3,

Monitoring and Measurement

Processes

Appendix 4, paragraph 10.1.4,

Monitoring and Measurement of

Products/Services

Appendix 4, paragraph 10.2,

Control of Non-Conforming

Products/Services

Appendix 4, paragraph 10.3, Data

Analysis

Appendix 4, paragraph 10.4,

Evaluation and Continual

Improvement

Appendix 4, paragraph 10.5,

Corrective Action

Criterion 4 — Management/Documents and

Records.

a.

Prepare, review, approve, issue, use, and revise

documents to prescribe processes, specify requirements,

or establish design.

b.

Specify, prepare, review, approve, and maintain

records.

Appendix 4, paragraph 6.2,

Documentation Requirements

NAP 414.1

1

-10-17

Appendix 8

AP8-3

DOE O 414.1 (ATTACHMENT 2) MSD

Criterion 5 — Performance/Work Processes.

a.

Perform work consistent with technical standards,

administrative controls, and other hazard controls

adopted to meet regulatory or contract requirements

using approved instructions, procedures, or other

appropriate means.

b.

Identify and control items to ensure proper use.

c.

Maintain items to prevent damage, loss, or

deterioration.

d.

Calibrate and maintain equipment used for process

monitoring or data collection.

Appendix 4, paragraph 9,

Operations

Appendix 4, paragraph 9.1,

Planning of Product and Service

Realization

Appendix 4, paragraph 9.2,

Determination of Requirements

Related to Products and Services

Appendix 4, paragraph 9.3, Review

of Requirements Related to

Products and Services

Appendix 4, paragraph 9.4,

Customer Communication

Appendix 4, paragraph 9.5, Control

of Production and Service

Provisioning

Appendix 8

AP1-8-4

NAP 414.1

1-10-17

DOE O 414.1 (ATTACHMENT 2) MSD

Criterion 6 — Performance/Design.

a.

Design items and processes using sound

engineering/scientific principles and appropriate

standards.

b.

Incorporate applicable requirements and design bases

in design work and design changes.

c.

Identify and control design interfaces.

d.

Verify or validate the adequacy of design products

using individuals or groups other than those who

performed the work.

e.

Verify or validate work before approval and

implementation of the design.

Appendix 4, paragraph 9,

Operations

Appendix 4, paragraph 9.1,

Planning of Product and Service

Realization

Appendix 4, paragraph 9.2,

Determination of Requirements

Related to Products and Services

Appendix 4, paragraph 9.3, Review

of Requirements Related to

Products and Services

Appendix 4, paragraph 9.4,

Customer Communication

Appendix 4, paragraph 9.5, Control

of Production and Service

Provisioning

Criterion 7 — Performance/Procurement.

a.

Procure items and services that meet established

requirements and perform as specified.

b.

Evaluate and select prospective suppliers on the basis

of specified criteria.

c.

Establish and implement processes to ensure that

approved suppliers continue to provide acceptable items

and services.

Appendix 4, paragraph 8.1,

Provisioning of Resources

NAP 414.1

1

-10-17

Appendix 8

AP8-5

DOE O 414.1 (ATTACHMENT 2) MSD

Criterion 8 — Performance/Inspection and

Acceptance Testing.

a. Inspect and test specified items, services, and

processes using established acceptance and performance

criteria.

b. Calibrate and maintain equipment used for

inspections and tests.

Appendix 4, paragraph 10,

Monitoring, Measurement,

Analysis, and Evaluation

Appendix 4, paragraph 10.1,

Monitoring and Measurement

Appendix 4, paragraph 10.1.2,

Internal Audit

Appendix 4, paragraph 10.1.3,

Monitoring and Measurement

Processes

Appendix 4, paragraph 10.1.4,

Monitoring and Measurement of

Products/Services

Appendix 4, paragraph 10.2,

Control of Non-Conforming

Products/Services

Appendix 4, paragraph 10.3, Data

Analysis

Appendix 4, paragraph 10.4,

Evaluation and Continual

Improvement

Appendix 4, paragraph 10.5,

Corrective Action

Criterion 9 — Assessment/Management Assessment.

Ensure that managers assess their management

processes and identify and correct problems that hinder

the organization from achieving its objectives.

Appendix 4, paragraph 5,

Integrated Management System

Appendix 8

AP1-8-6

NAP 414.1

1-10-17

DOE O 414.1 (ATTACHMENT 2) MSD

Criterion 10 — Assessment/Independent Assessment.

a.

Plan and conduct independent assessments to measure

item and service quality, to measure the adequacy of

work performance, and to promote improvement.

b.

Establish sufficient authority and freedom from line

management for independent assessment teams.

c.

Ensure persons who perform independent assessments

are technically qualified and knowledgeable in the areas

to be assessed.

Appendix 4, paragraph 10,

Monitoring, Measurement,

Analysis, and Evaluation

Appendix 4, paragraph 10.1,

Monitoring and Measurement

Appendix 4, paragraph 10.1.2,

Internal Audit

Appendix 4, paragraph 10.1.3,

Monitoring and Measurement

Processes

Appendix 4, paragraph 10.1.4,

Monitoring and Measurement of

Products/Services

Appendix 4, paragraph 10.2,

Control of Non-Conforming

Products/Services

Appendix 4, paragraph 10.3, Data

Analysis

Appendix 4, paragraph 10.4,

Evaluation and Continual

Improvement

Appendix 4, paragraph 10.5,

Corrective Action

NAP 414.1

1-10-17

Appendix 9

AP9-1

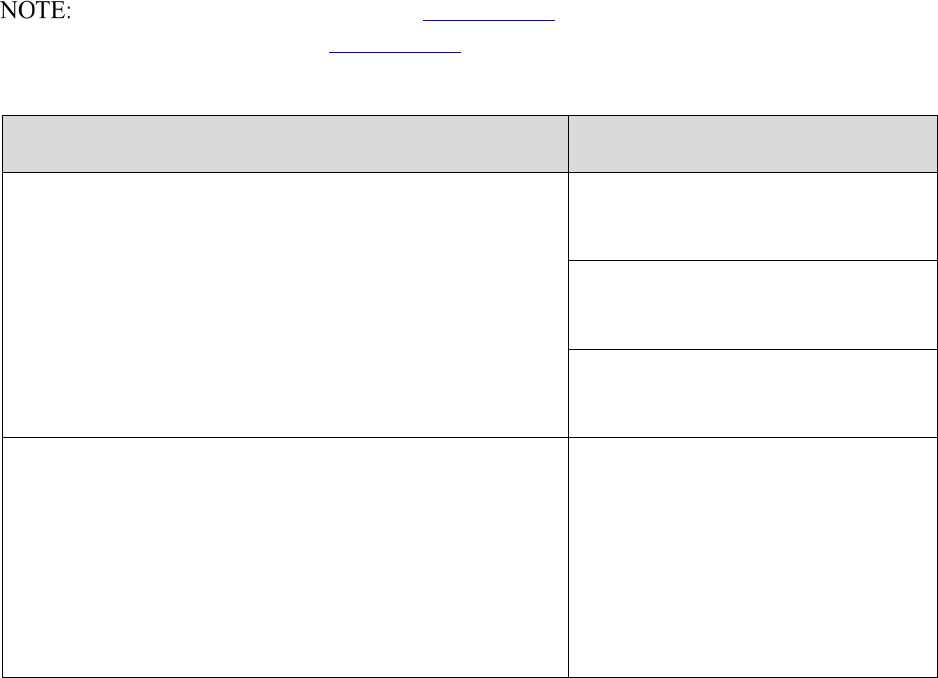

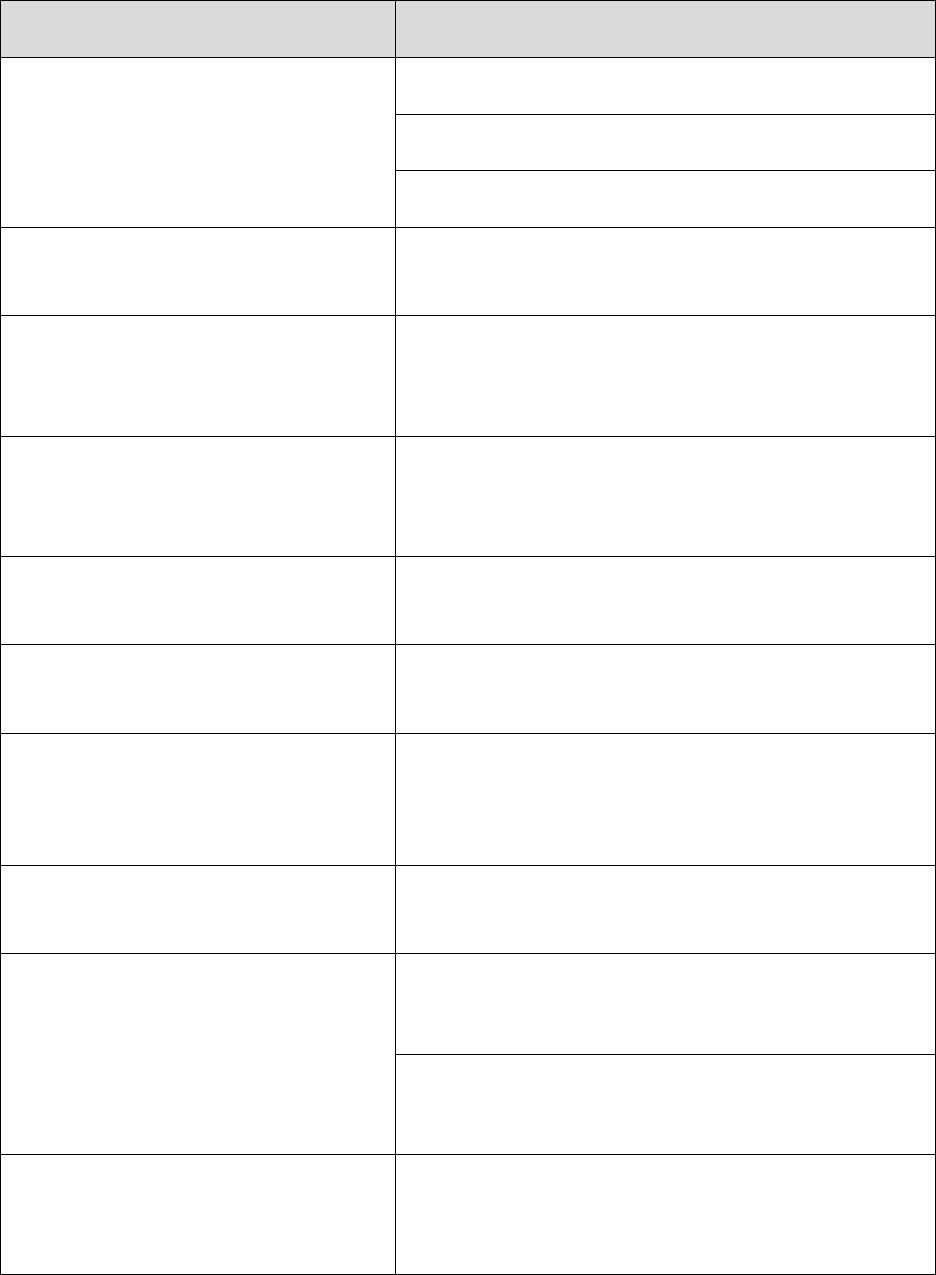

APPENDIX 9. MSD-ISO 9001:2015 TRACEABILITY MATRIX

The select/applicable principles from ISO 9001:2015 are identified in this appendix to

demonstrate a crosswalk between ISO 9001:2015 and the MSD. It contains no additional

requirements/principles.

MSD ISO 9001:2015

Appendix 4, paragraph 5, Integrated

Management System

9.3.1 General

(Subparagraph of Management review)

Appendix 4, paragraph 6.1, General

Requirements

4.4.1

(Subparagraph of Quality management system and its

processes)

Appendix 4, paragraph 6.2,

Documentation Requirements

4.4.2 To the extent necessary, the organization shall:

(Subparagraph of Quality management system and its

processes)

7.5.1 General

(Subparagraph of Documented information)

7.5.2 Creating and updating

(Subparagraph of Documented information)

Appendix 4, paragraph 6.2.3, Control

of Documents

7.5.3.1

(Subparagraph of Control of documented

information)

7.5.3.2

(Subparagraph of Control of documented

information)

8.1 Operational planning and control

Appendix 4, paragraph 7.1,

Leadership and Commitment

5.1.1 General

(Subparagraph of Leadership and commitment)

Appendix 9

AP9-2

NAP 414.1

1-10-17

MSD ISO 9001:2015

Appendix 4, paragraph 7.2, Customer

Focus

5.1.2 Customer Focus

Appendix 4, paragraph 7.2.1, Quality

Policy

5.2.1 Establishing the quality policy

Appendix 4, paragraph 7.3.1, Quality

Objectives

6.2.1

(Subparagraph of Quality objectives and planning to

achieve them)

6.2.2

(Subparagraph of Quality objectives and planning to

achieve them)

Appendix 4, paragraph 7.3.2,

Processes and Procedures

6.1.1

(Subparagraph of Actions to address risks and

opportunities)

6.1.2 The organization shall plan:

(Subparagraph of Actions to address risks and

opportunities)

Appendix 4, paragraph 7.4.1,

Responsibility and Authority

5.3 Organizational roles, responsibilities, and

authorities

Appendix 4, paragraph 7.4.2,

Communication

7.4 Communication

5.2.2 Communicating the quality policy

Appendix 4, paragraph 8.1,

Provisioning of Resources

7.1.1 General

(Subparagraph of Resources)

Appendix 4, paragraph 8.2.1,

Assignment of Personnel

7.1.2 People

NAP 414.1

1

-10-17

Appendix 9

AP9-3

MSD ISO 9001:2015

Appendix 4, paragraph 8.2.2,

Competence, Awareness, and

Learning

7.1.2 People

7.2 Competence

7.3 Awareness

Appendix 4, paragraph 9.1, Planning

of Product and Service Realization

8.1 Operational planning and control

Appendix 4, paragraph 9.2,

Determination of Requirements

Related to Products and Services

8.2.2 Determining the requirements for products and

services

Appendix 4, paragraph 9.3, Review of

Requirements Related to Products and

Services

8.2.3 Review of requirements for products and

services

Appendix 4, paragraph 9.4, Customer

Communication

8.2.1 Customer communication

Appendix 4, paragraph 9.5, Control of

Production and Service Provisioning